IIoT: An introduction to Manufacturing IoT

Just as it has already altered consumer markets for appliances and wearables, connected technology is also on track to fundamentally change the manufacturing industry as businesses step up their investment in industrial IoT (IIoT) solutions.

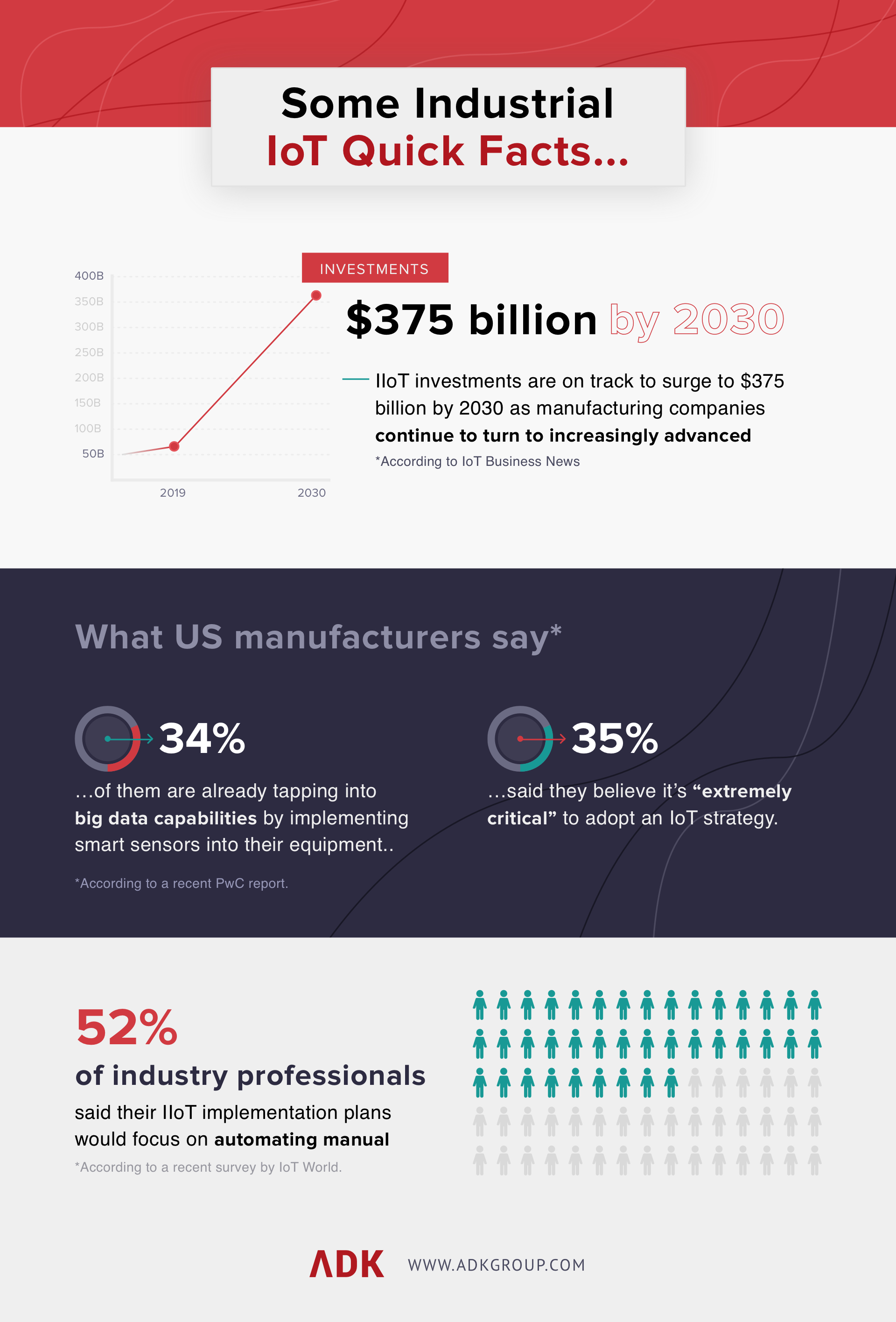

Recent data indicates that Industrial Internet of Things (IIoT) investments are on track to surge to $375 billion by 2030 as manufacturing companies turn to advanced technologies such artificial intelligence (AI), machine learning, and augmented reality in an effort to boost the operational efficiency of their businesses. This investment is likely to increase further as manufacturers search for solutions that will enable their facilities to remain active and keep their workers safe amid the COVID-19 pandemic.

Even as the IIoT market expands, however, some manufacturers and industrial businesses are reluctant to invest in connected technologies. A PwC report found only 35 percent of US manufacturers are tapping into big data capabilities by implementing smart sensors into their equipment. The same report also found just 34 percent of US manufacturers believe it is “extremely critical” to adopt an IoT strategy.

These rates of activity could indicate that many manufacturing companies view IIoT as having an uncertain ROI. Others may be uncertain if the older, analog equipment used at their facilities can even be fitted with connected technology.

In an increasingly connected world, manufacturers who choose to make the investment in IIoT will be in a stronger position to respond to production issues, maintain equipment, track assets, staffing issues, and manage inventory than their competitors who have not yet implemented connected systems.

The following brief outlines top use cases of IIoT and demonstrates how connected technologies can help manufacturers pursue a long-term growth strategy.

Industrial IoT Application 1: Access To Real-Time Data

One of the key benefits of connected technologies is immediate access to information directly from the shop floor of a facility. By implementing IIoT-connected sensors into your equipment and facilities, you can gain access to real-time data and insights on how you can improve the quality of your production output, staffing levels, customer services, and identify waste patterns.

Industrial IoT Application 2: Predictive Maintenance Capabilities

Access to real-time data can also help the manufacturing market address a long-standing problem: reducing equipment downtime and boosting equipment uptime. Whenever machines are not operating, you risk falling behind on your production output goals and losing business to competitors. IIoT sensors can provide you with predictive maintenance capabilities that help them determine if equipment is meeting its output expectations or underperforming.

If a problem is flagged, you can immediately schedule a service call before a serious problem develops.

Manufacturers who invest in more advanced technologies like AI, machine learning and cloud computing systems can also unlock the potential of predictive analytics and anticipate numerous issues before they arise.

Industrial IoT Application 3: Safeguarding Manufacturers’ Supply Chains

In most manufacturing environments, a vast supply chain network is required in order to assemble products. IoT solutions for manufacturers can be used to track the inventory of numerous production components and provide manufacturers with insights into their available materials. These industrial IoT solutions can also help manufacturers determine how long it could take for specific materials to be delivered to their facilities and plan their output schedules accordingly.

Industrial IoT Application 4: Automating Manual Processes

Being able to access real-time data can also provide manufacturers with greater flexibility to automate certain tasks that previously needed to be performed manually. Maximizing automated opportunities appears to be a top priority for many manufacturers.

A recent survey by IoT World found that 52 percent of industry professionals said their IIoT implementation plans would focus on automating manual processes. IIoT technology enables manufacturers to automate numerous processes, such as automatically re-ordering supplies once the inventory of certain items reaches a certain level, reporting on the efficiency of your machines, or identifying equipment that needs to be replaced.

Industrial IoT Application 5: Smarter Asset Tracking

Re-ordering and reporting are just two of several opportunities for manufacturers to automate the production process and shift away from manual workflows. Access to real-time data can also provide manufacturers with the ability to track the location of industrial assets remotely.

Manufacturing equipment can be fitted with radio frequency identification (RFID) solutions that can spare manufacturing employees from the manual (and sometimes error-prone) task of inputting a specific code containing multiple numeric or alphabetic characters. These can transmit different types of data about each asset, including their location, serial number, model number, and physical attributes.

The movements of different assets can be automatically logged and stored in a cloud-based platform. This can provide leaders information about where assets are located, enabling them to develop production plans using the latest data.

Industrial IoT Application 6: Improving Worker Safety

Employees can also benefit from safer working conditions when manufacturers put IIoT technologies to work at their facilities. Connected systems can introduce condition monitoring capabilities that alert manufacturers, shop floor managers, and others about hazardous conditions like extreme temperature, the presence of dangerous chemicals, or gas leaks.

The latest figures from the U.S. Bureau of Labor Statistics found more than 5,000 U.S. workers died in work-related injuries in 2018. Connected technologies could help manufacturers reduce the likelihood of work-related fatalities and demonstrate to their employees that they take their safety seriously. This investment could also deliver a strong ROI by making the manufacturing company that invests in worker-focused IIot solutions more appealing to employees compared to its competitors.

Industrial IoT Application 7: Improving Customer Relationships

Manufacturers can use connected technology to assess the quality of their products during each stage of the production cycle. The same technology can also provide insights into how customers are engaging with their products. A recent Deloitte report, for example, outlines how automakers are using connected sensors to remain engaged with customers in the aftermarket by delivering data about their vehicle’s performance. This provides automakers with a crucial opportunity to retain existing customers and improve their product’s performance.

In the end, IIoT is about connectivity and the freeflow of data. Giving equipment eyes, ears, and a voice will unlock the next wave of advantages for industrial leaders.

What’s next for Industry 4.0 and beyond?

The manufacturing space has been facing unprecedented challenges, even before the COVID-19 pandemic began unfolding, and even fell into a recession last year.

Connected technology could be the key for many manufacturing businesses to enhance operations, build stronger, more reliable supply chains, protect workers, and forge engaged relationships with customers.

In order for manufacturers to realize the benefits that IIoT solutions can provide, they must first be prepared to make the investment in the technology — a step many manufacturers are hesitant to take. The manufacturers who are willing to take a chance on connected technologies stand to be better prepared to address the demands of a highly connected, global economy.

Manufacturers who want to enhance their operations should consider working with a technology partner who can help them navigate uncertain terrain and guide them to a more connected, more efficient, and more profitable future.

That’s where ADK Group comes into play. Our experts work closely with your team to help create a custom technology solution that enables you to move past your competitors.

Connected technology is changing the rules of manufacturing. Those manufacturers who do not adapt risk getting left behind. Let ADK Group be your guide to competing in a highly connected industrial landscape.